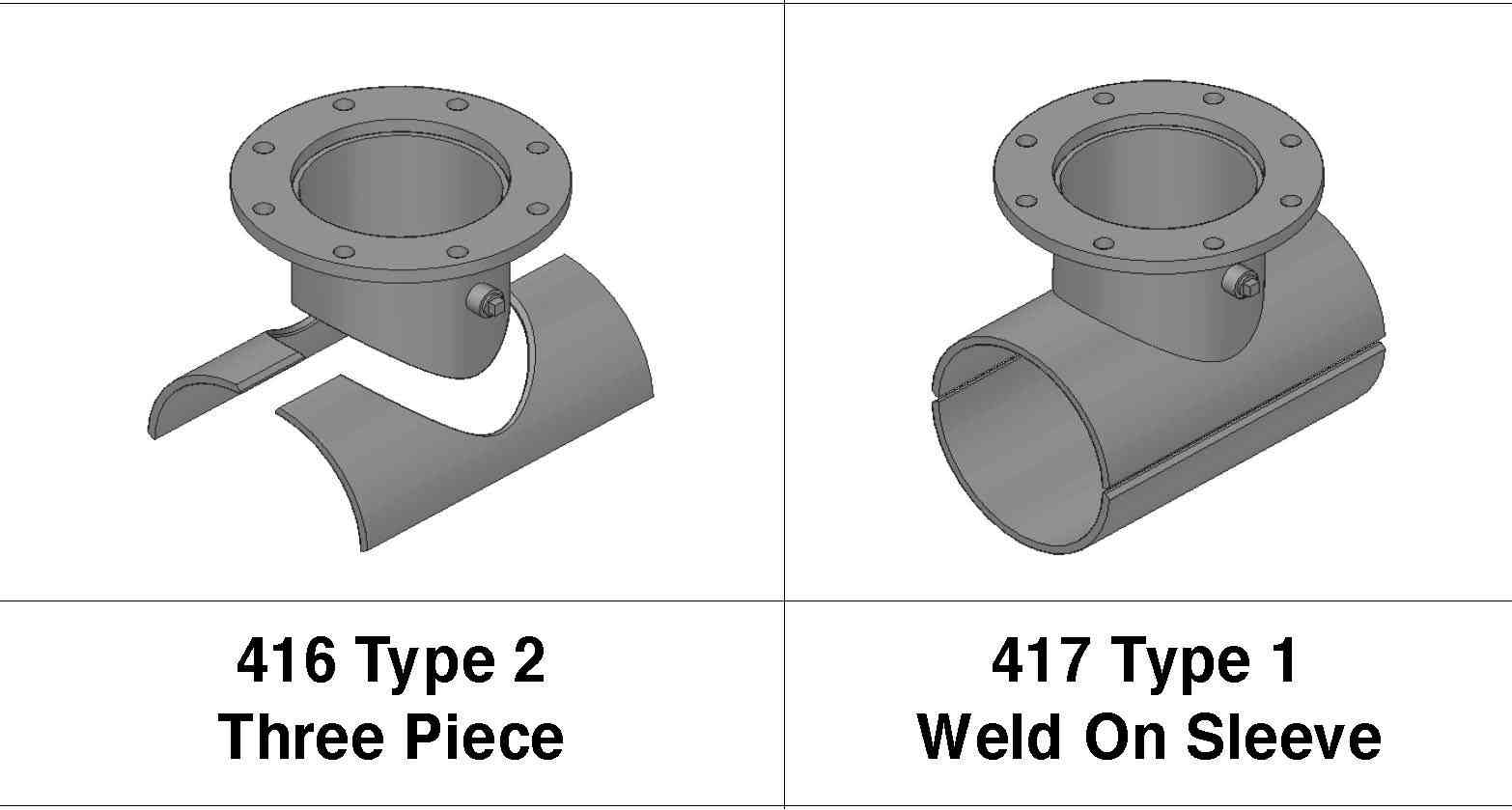

Split Weld Tee 2-3 Piece Fittings

Tapping sleeves shall be the high strength type, made of a minimum material strength of ASTM 285 Grade C, ASTM A-36 Steel, or an equivalent. Flanged outlets shall be AWWA C207 Class D, ANSI 150 lb. drilling, recessed for tapping valve per MSS-SP60; outlets 2” – 12” rated for 175 PSI* maximum operating pressure. Tapping sleeve shall be furnished with corrosion resistant shop coat paint primer. Tapping sleeves shall be the high strength type, made of a minimum material strength of ASTM 285 Grade C, ASTM A-36 Steel, or an equivalent. Flanged outlets shall be AWWA C207 Class D, ANSI 150 lb. drilling, recessed for tapping valve per MSS-SP60; outlets 2” – 12” rated for 175 PSI* maximum operating pressure. Tapping sleeve shall be furnished with corrosion resistant shop coat paint primer.

*Higher test and working pressure ratings available upon request. Series tapping sleeves are ANSI/NSF Standard 61, and Standard 61 Annex G Certified. Series tapping sleeves meet MSS-SP124 and ANSI/AWWA standard C223 fabricated steel, and stainless steel tapping sleeves, as applicable.

|

Other designs offered by JCM, price on application |

|

Material Specification: Weld-on tapping outlet and the weld-on tapping sleeve body: ASTM 283 Grade C, ASTM 285 Grade C, ASTM A-36 Steel or an equivalent. Flange: AWWA C207 Class D, ANSI 150 lb. Drilling, recessed for tapping valve per MSS-SP60. Optional flanges available upon request. Finish: Heavy coat of corrosion resistant shop coat primer. Service Rating: 2" to 12" Outlets: 175 PSI. Higher service rating available for specific applications and sizes.

Custom built weld-on fittings are available in a variety of designs to suit the application and end user needs. Contact JCM for specific submittal information.

Split Weld Tee Free Quote

|